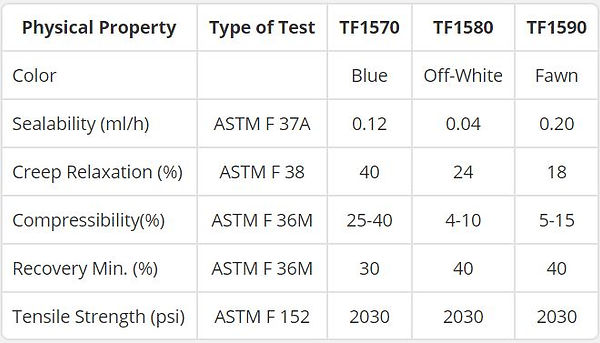

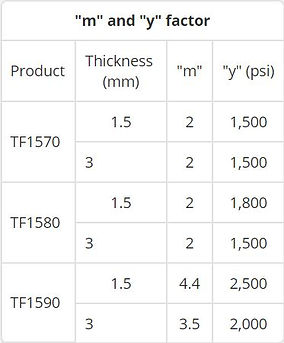

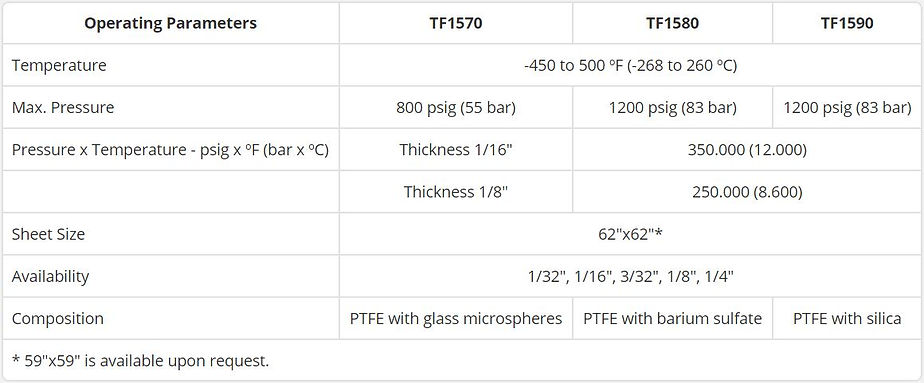

Tealon (Filled PTFE Sheet / Gaskets)

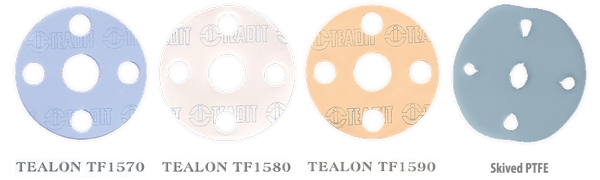

Tealon TF1570 | Blue

Tealon TF1570 is filled with glass microspheres and is suitable for aggressive chemical applications. It meets FDA conformance for service within food and pharmaceutical applications. TF1570 is the preferred material for fragile flanges, glass lined equipment or other applications that require higher compressibility.

Approvals: DVGW — TA-Luft — FDA

Tealon TF1580 | Off-White

Tealon TF1580 is filled with barium sulfate and is suitable for strong caustic fluids. It meets FDA conformance for service within food and pharmaceutical applications. 1580 can be used in a wide range of applications due to its vast resistance to most chemical products. It is compatible with strong acids along with strong caustics, making it the most diverse material within the Tealon family. With the off-white color of 1580, this material is also suitable for processes where contamination is not tolerated. Tealon 1580 meets and has been approved by BAM for oxygen service.

Approvals: DVGW — TA-Luft — FDA — BAM — Chlorine Institute

Tealon TF1590 | Fawn

Tealon TF1590 is filled with silica and meets a wide range of aplications. It is suitable for general service, strong acids and moderate caustic solutions. It meets FDA conformance for service within food and pharmaceutical applications. TF1590 has easily passed the Hot Compression Test with outstanding results.

Approvals: DVGW — TA-Luft — FDA — Chlorine Institute

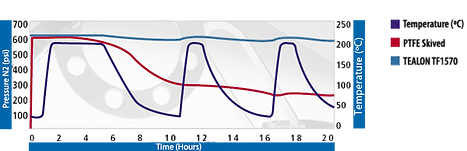

Hot Compression Test

This performance test measures the behavior of rPTFE and PTFE gaskets in a real world environment. The chart below shows a comparison between conventionally skived PTFE and Tealon. The gaskets we tested simulated a real world application including thermo-cycling. The skived PTFE gasket showed a very high leak rate, losing 60% of its initial pressure by the end of the test.

The Tealon® gasket lost only 6% of its initial pressure by the end of the test and showed a leak 10 times less than that of the skived PTFE gasket. The pictures below, show the gaskets after the test and exhibit the dimensional stability of Tealon as compared to the noticeable creep of the skived PTFE gasket.

Thermo-Cycling Leak Test

Temperature cycles from 30º C to 200ºC, with seating stress of 5000psi and using a gasket thickness of 1/8".

Thermo-Cycling Leak Test Condition

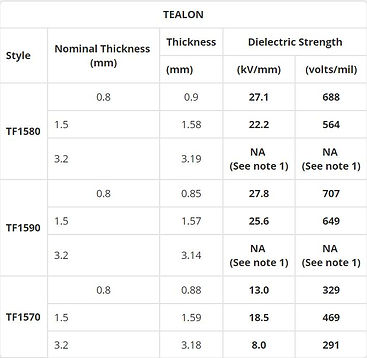

Tealon Dielectric Properties

Note 1: exceeds 50kV, which is the equipment capability.